Complete lines

At Carbon Blue, we design complete production lines specifically tailored to micro-factories capable of meeting the majority of plastic recycling needs, including PP, PE and PET.

We are also open to exploring other types of plastic materials depending on your specific needs.

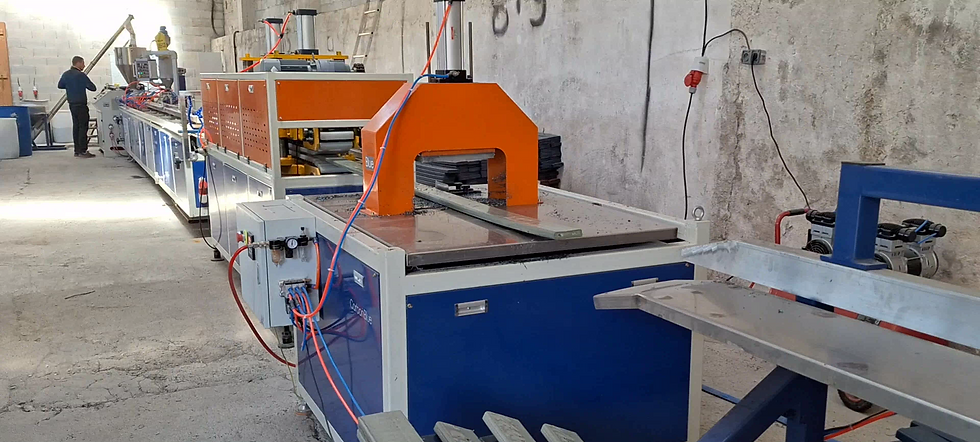

Plate manufacturing line

Three key steps: reduction (grinding into flakes), melting (transformation into sheets) and manufacturing (durable finished products).

They make local recycling possible and transform plastic into a useful resource.

Type de plastique | PEHD, PP, PS ou PVC |

Recycling | 150T/year (or approximately 480T of CO2 captured) |

Personnel | 2 personnes |

Power | 100 kW |

Card manufacturing line

This unit creates unique products composed of a recycled black PE plastic core, wrapped in a thin colored layer. An innovative solution for recycling waste while providing an aesthetically pleasing finish.

Type of plastic | Soft plastics |

Recycling | 300T/year (or approximately 960T of CO2 captured) |

Staff | 2 people |

Power | 100 kW |

Pellet recycling line

This ultra-mobile and modular unit transforms flexible plastics, such as exhibition carpets.

An agile and local solution for recycling where waste originates.

Closer, faster, more useful.

Type of plastic | Soft plastics |

Recycling | 300T/year (or approximately 960T of CO2 captured) |

Staff | 2 people |

Power | 100 kW |

PET bottle recycling line

Millions of plastic bottles litter beaches, end up in Africa, or are shipped to islands with no recycling options. Our local units process this waste on site, recreate the material, and distribute the volumes.

Type of plastic | Flexible plastics |

Recycling | 450 tonnes/year, or approximately 1,440 tonnes of CO2 captured |

Staff | 5 people |

Power | 150 kW |

Water | 3 m3/hour |